|

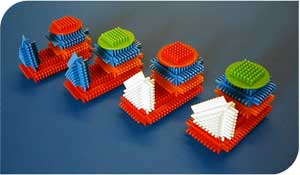

The training session begins with a production line set up to

build the four products (shown here) using traditional batch production

methods. There are four assembly stages, which can be associated with

similar, real life processes, a component stores and at least one supplier.

During the production run the customer places a series of orders for

the product, which causes more demand for kits of parts for the

|

production line. At the end of the timed session the production line

is halted and the process is evaluated and performance critically measured.

This includes counting the value of products manufactured, the cost

of any defective products found at final inspection, the cost of raw

materials on the production line and the cost of part-built products

(work in progress).

|

The trainees are then invited to discuss the results and to suggest suitable

ways of improving production techniques and reducing costs. Two of these suggestions

are then implemented and the game is run again to assess the impact of the

changes. The process of making changes, testing and evaluation is repeated,

usually four times, reducing until a more effective production line has been

created.

The key

areas for the improvement of business performance are typically:-

-

Production Line Layout Improving the flow

of materials with lineside supply and the flow of sub assemblies through

the process to a One Piece Flow.

-

Fool-proofed Quality Presenting the raw

materials in such a manner as to reduce the possibility of incorrect orientation

during assembly. Also development of better assembly instructions and

quality checking.

-

Cellular Manufacturing Changing the production

method from batch oriented to cellular flow manufacturing reducing the

amount of stock on the production line and checking quality at all stages

of manufacture

The game

is supplied fully boxed with comprehensive instruction manuals.