The machine also contains a simulated fuse, similar to the parts

described above. A badly maintained machine will consume more power

than a good machine. Failure of the operator to monitor the power

indicator and attempting to run a worn machine at high speeds will

cause a power overload and the fuse will blow. This will cause the

machine to stop and the production output will once again be compromised

while the fuse is replaced.

|

|

The simulated parts will automatically reset themselves after approximately

10 minutes so that they can be used again in the next simulated production

run.

At the end of each session the trainees can calculate the OEE figure

using the data produced during the production run. The trainees can

then discuss possible areas for improvement, better operating and

maintenance procedures, etc. and then run the game again to test out

their new theories.

|

This product is designed to teach the principles of Overall Equipment Effectiveness

(OEE). The game electronically simulates all the functions and characteristics

of an actual machine in the workplace and enables the trainees to develop

the correct operating procedures and maintenance schedules in order to obtain

the most efficient working conditions.

The operating conditions of the machine are indicated on the front panel

displays. The three displays to the left show the power consumption, operating

speed and oil reservoir level respectively. The machine operator may adjust

the running speed of the machine but must also be aware that an increase in

speed will also cause an increase in power consumption. The machine also consumes

oil while it is running and the level in the reservoir needs to be maintained

otherwise excess wear will be caused. The effects of this will become noticeable

as the machine begins to slow down and the power consumption starts to increase.

The condition of the machine will also have an effect on the quality of

the products manufactured. A badly maintained machine will produce more rejects

than a well looked after machine. The number of good and bad products made

is shown on the displays at the right hand end of the front panel.

The machine also simulates actual wear and tear on its component parts.

There are 3 removable parts inside the machine, simulating actual components,

which show their condition using four coloured lights on each part.

A green light shows that the component is in good condition but any

build up of wear will cause a yellow light to show and eventually a

red light will show. When this happens the machine will be

|

|

brought to a halt as the component has failed completely and needs

to be replaced. The number of spare parts is limited (as in real life)

so the trainees are encouraged to maintain the machine correctly. The

lengthy stoppage for repair also causes the production output to be

considerably reduced. Preventative maintenance can also be carried out

while the machine is running to reduce wear and prevent failure of the

component parts.

|

The game is supplied complete with detailed instruction manual, transit

case and 1 year warranty.

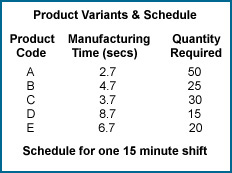

The machine is set up to produce a range of different products, each of

which takes a different amount of time to produce. The trainees are given

a typical production schedule showing the quantity of each product required

in the allocated time. It is necessary to shut down the machine before changing

over from one product to another. The start and stop procedure is also time

consuming.